How does a cryogenic valve or low temperature valve work?

For temperatures below minus 50 degrees Celsius, do not use extended valve stems. For temperatures below minus 50 degrees Celsius, the length of the stem depends on the specific temperature. The cryogenic valve is mainly used to transport low-temperature medium such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, and liquefied petroleum oil, which not only is easy to explode and flammable, but also becomes a gas when the temperature is vaporized, with the volume expanded hundreds of times.

The low temperature valve material is very important. If it is not correct, it will cause leakage inside and outside the valve body casing and sealing surface. The unqualified comprehensive mechanical capacity, strength and hardness of the parts will cause breakage. If the LNG leaks, it will explode. Therefore, materials are the main problem in the design and manufacture of LNG valves. The body and bonnet consist of LCB (-46 Deg. C), LC3 (-101 Deg. C), and CF8 (SS304) (-196 Deg. C).

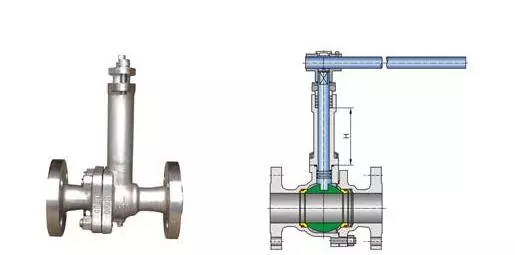

The low temperature valve with an extra-long stem structure is designed to reduce the heat entering the valve from the outside; and to ensure that the packing gland temperature is above 0 degrees Celsius, so as to ensure that the packing is unaffected. Finally, it avoids parts above the valve stem and bonnet from freezing or frosting due to a decrease in the temperature of the filler.

The design of the cryogenic valve is mainly to prevent the expansion of the L; L is the package of the upper surface of the rear seat from the bottom, depending on the thermal conductivity of the material, the heat transfer area, the surface heat transfer coefficient, and the heat dissipation area, the calculation process of which is very complicated, usually by experiment.

The working conditions of the cryogenic valve are very harsh. The medium is usually flammable and highly permeable. The minimum working temperature can reach -260 degrees Celsius and the maximum working pressure can reach 10 mpa. In this case, the design, manufacture, and inspection of the cryogenic valve are generally different from those of the forged ball valve, the embedded ball valve, and the metal seat ball valve.